ABOUT US

ABOUT US

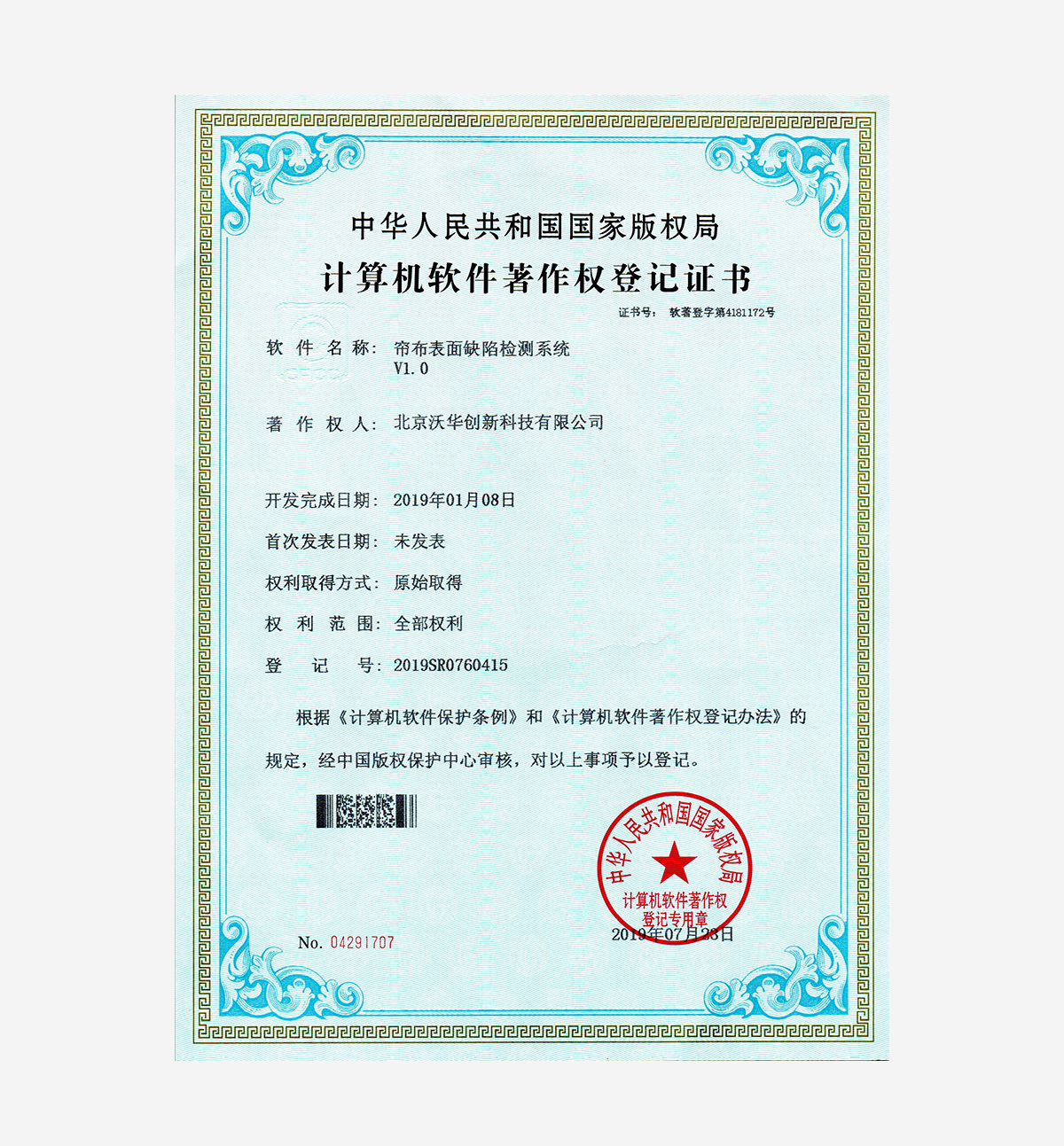

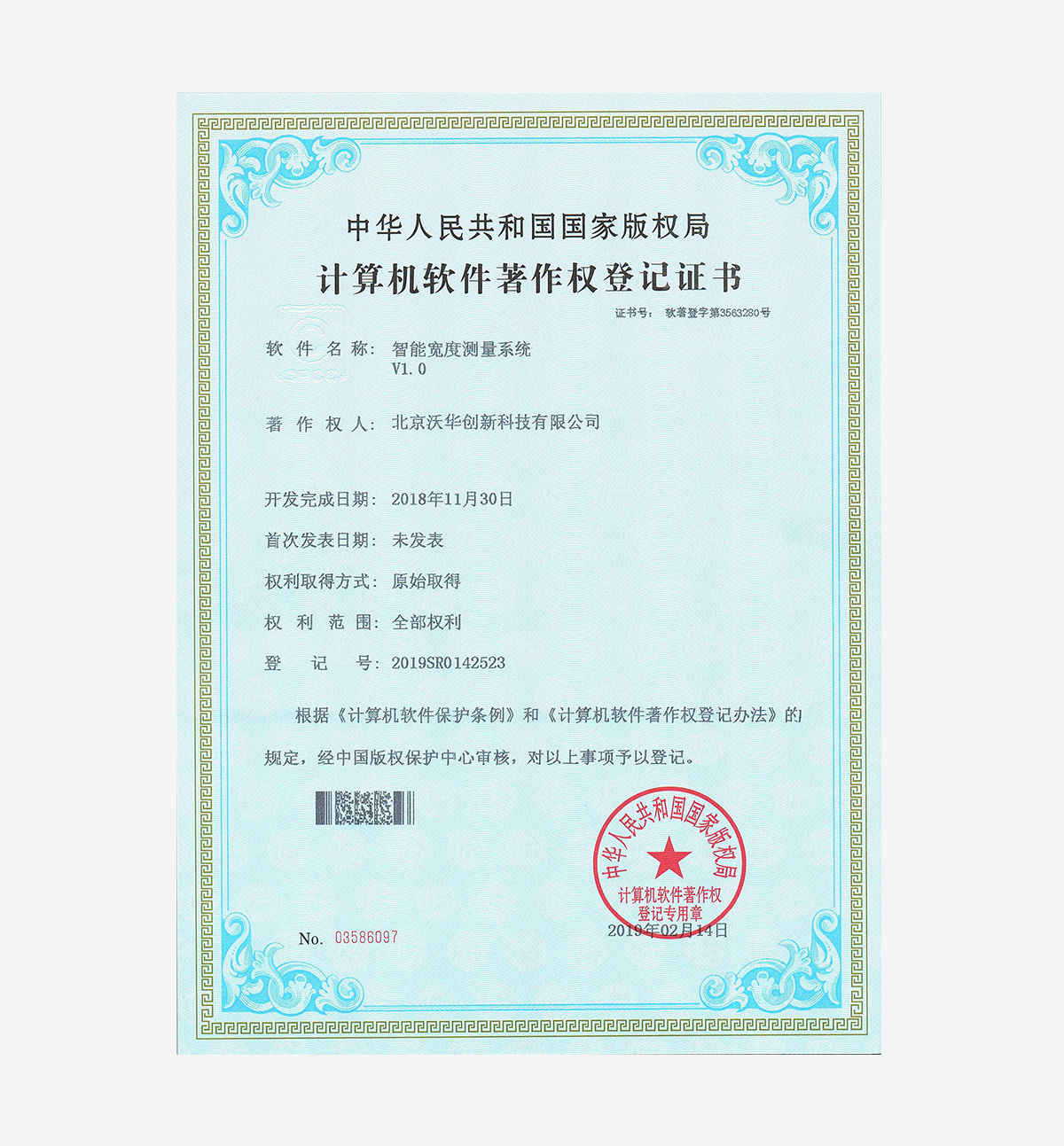

Beijing Wohua Innovation Technology Co., Ltd. is an innovative technology enterprise integrating design, development, production, sales and service. Founded in July 1997, it is located in Shangdi High-tech Park in Zhongguancun. With years of accumulation in electronics, machinery, automation and other aspects, relying on the advantages of Zhongguancun High-tech Park, a group of experienced and advanced management high-quality talents have been gathered, laying a solid foundation for the development of the company. As the earliest business segment of the company, since its establishment in 1997, the company has been committed to the development, development and technical service of quality testing equipment for the production process of the rubber tire industry, as well as the provision of complete sets of equipment and services for tire production. The main products and technologies include: tire calendering rubber sheet thickness measurement and control system, tread sidewall extrusion line section thickness measurement system, tread/sidewall width measurement and control system The inner liner thickness measurement and control system and the rubber component material CCD width measurement system provide a full range of detection technologies and services for the tire production process quality detection and control field. |

Adhering to the development idea of "quality first, service first", the company passed the ISO9001 international quality system certification in 2003. In 2008, after being approved by the Beijing Municipal Commission of Science and Technology, it was recognized as a high-tech enterprise and became a member of the Beijing Zhongguancun High-tech Enterprise Association. In the new century, we adhere to the business philosophy of "scientific and technological innovation, pursuit of excellence", and wholeheartedly provide you with high-quality products and satisfactory services.

-

Company vision

To become a global brand enterprise in the field of automated testing

-

Corporate mission

We are committed to providing more intelligent test solutions and services, and continue to create value for customers, employees and shareholders

-

Core values

Gratitude, integrity, innovation and excellence

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:www.wohuakeji.com

Web:www.wohuakeji.com